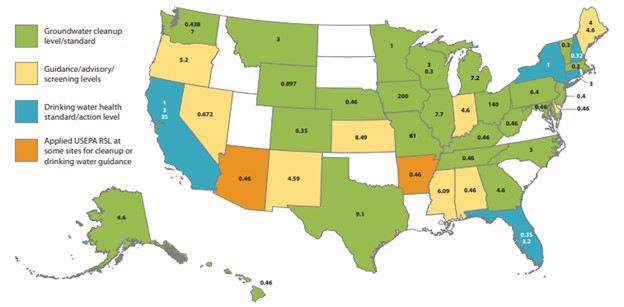

1,4-dioxane has been used as a stabilizing agent in chlorinated solvents and has emerged as a significant groundwater contaminant in the US. Although there is no federal maximum contaminant level (MCL) for 1,4-dioxane, various states have established the drinking water and/or groundwater standards at or below 1 microgram per liter (mg/L). Recent developments in the use of cometabolic bioremediation combined with bioaugmentation, however, have proven to be an effective technology to treat 1,4-dioxane to meet low regulatory limits.

(Source from ITRC Regulatory Framework for 1,4-dioxane released in February 2021 )

Cometabolic vs Metabolic Bioremediation

Bioremediation is an electron transfer process mediated by microorganisms. The key difference between cometabolic and metabolic bioremediation is whether the contaminant is required for microorganism growth. Metabolic bioremediation is the process that microorganisms obtain energy or biomass from degrading contaminants, which act either as electron donors or electron acceptors. In the contrast, co-metabolic bioremediation is the process that microorganisms generate non-target enzymes and do not gain growth benefit from degrading contaminants. When the contaminant is essential for microorganism growth, a threshold concentration of the target contaminant is required to maintain bioremediation. Cometabolic remediation does not have a limitation on the contaminant concentrations but cometabolic substrates are required to support microorganism growth.

Cometabolic Degradation for 1,4-Dioxane and Commingled Plume

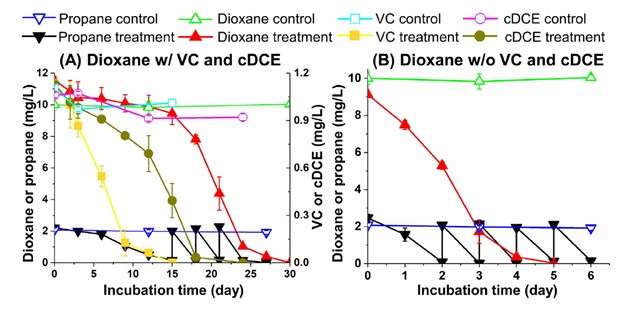

Significant 1,4-dioxane soil sources are not typically present, due to 1,4-dioxane’s low sorption capacity to soil and miscibility with water. Additionally, 1,4-dioxane migrates with water at rates much faster than the comingled chlorinated solvents resulting in diluted 1,4-dioxane plumes. To sustain metabolic bioremediation, 1,4-dioxane concentrations should be above or near 50 mg/L. At most sites in the US, 1,4-dioxane concentrations are below the threshold for metabolic bioremediation. Further, cis-1,2-dichloroethene (DCE) and vinyl chloride (VC), the daughter products generated from the chlorinated solvent degradation, are known inhibitors for 1,4-dioxane bioremediation. In fact, in a diluted plume where cis-1,2-DCE and VC are the main chlorinated solvent compounds, 1,4-dioxane could be persistent for decades and won’t be degraded until cis-1,2-DCE and VC are eliminated.

Reductive dechlorination, a metabolic degradation pathway, is the most well-known degradation pathway for chlorinated solvents. However, the daughter products including cis-1,2-DCE and VC can also be degraded via cometabolic bioremediation. As a matter of fact, the first cometabolic bioremediation was implemented to remediate cis-1,2-DCE. Therefore, cometabolic bioremediation can treat both 1,4-dioxane and chlorinated solvents. Once the chlorinated solvents are remediated, 1,4-dioxane can be degraded rapidly via cometabolic remediation (Figure 2).

VC was degraded first, followed by cis-1,2-DCE degradation. After the elimination of daughter products, a complete 1,4-dioxane reduction occurred in 10 days. The data is from the document “Sequential Anaerobic and Aerobic Bioaugmentation for Comingled Groundwater Contamination of Trichloroethene and 1,4-Dioxane.”

Implementation of Cometabolic Bioremediation

The biodegradation of 1,4-dioxane via metabolic or cometabolic processes occurs under aerobic (oxygen-rich) conditions. To enhance cometabolic bioremediation, an electron acceptor, such as oxygen, and an electron donor (as cometabolic substrate), such as propane, can be delivered to the subsurface. In addition to oxygen and the cometabolic substrate, the microbes that can efficiently degrade 1,4-dioxane and chlorinated solvents are also required to be present in the subsurface for cometabolic bioremediation to be successful. Indigenous microbes may not contain effective cometabolic degraders for 1,4-dioxane. If necessary, a bioaugmentation culture may be added to increase the effective degrader population to the needed threshold levels (104 cells per milliliter) for effective cometabolic bioremediation of 1,4-dioxane and chlorinated solvents in the subsurface. As shown in Figure 2, the addition of bioaugmentation culture, DD4 (consisting of Azoarcus sp.) results in highly efficient cometabolic remediation of 1,4-dioxane and chlorinated solvents. DD4 has been very successful because of its high proliferation rate and high mobility in the subsurface. The addition of DD4 along with air and propane can be the key to successful cometabolic remediation of 1,4-dioxane.

For in-situ implementation of cometabolic bioremediation, air (oxygen) and propane gas can be injected through conventional wells. Sequential injection of air (oxygen) and propane gas is a common practice for subsurface gas delivery. Cometabolic bioremediation was first implemented for chlorinated solvents in the 1990s’; thus, the technology is not considered innovative. However, the discovery of the novel cometabolic degraders including DD4 is the most recent advance for this technology. The bioaugmentation culture can be injected as a solution through the same gas injection wells. Alternatively, a reactive barrier consisting of sparge points to deliver air (oxygen), propane gas, and the bioaugmentation culture to enhance cometabolic bioremediation has also been proven to be a successful approach to manage large and dilute plumes consisting of both 1,4-dioxane and chlorinated solvents.

Posted In: Articles

Tagged In: Industrial, Research