Facilities that produce asphalt pavement mixtures (APM) typically qualify as minor sources of air pollution, but they nonetheless sometimes generate public concerns over siting and permitting.

APM comprises gravel and sand aggregates (~95% by mass) combined with petroleum-based asphalt cement (~5%). Recycled asphalt pavement (RAP) is also commonly incorporated into the APM, which is produced at temperatures from 300-350°F to allow for its application at worksites. From a regulatory perspective, the main source of pollutant emissions at an APM plant results from fuel combustion to dry and heat the aggregate materials. Concerns over APM plants, however, often focus on volatile chemicals associated with the liquid asphalt cement.

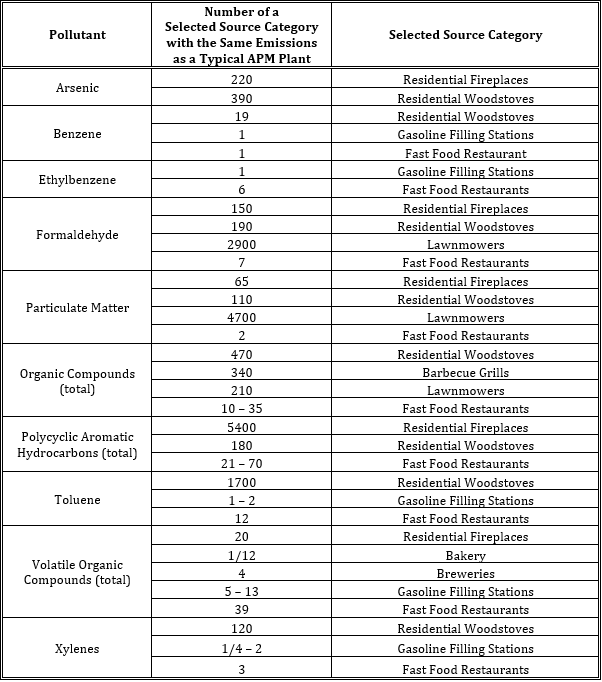

The U.S. Environmental Protection Agency has extensively studied and characterized emissions from APM plants, examining both stack and fugitive emission sources, and also both criteria pollutants subject to National Ambient Air Quality Standards and air toxics subject to Hazardous Air Pollutant (HAP) regulations. On behalf of the National Asphalt Paving Association, Sanborn Head used this information to update a study that compares emissions from a typical APM plant to air pollutant releases from other commonplace sources. The project report “Emissions Comparison: Asphalt Pavement Mixture Plants and Select Source Categories” can be obtained by filling out the request below. A summary table of the emissions comparisons is provided as follows (see the project report for details). As examples, benzene emissions from a typical APM plant are the same as those from 19 residential woodstoves or 1 gasoline filling station, and volatile organic compound (VOC) emissions from a bakery are about 12 times larger than those from a typical APM plant.

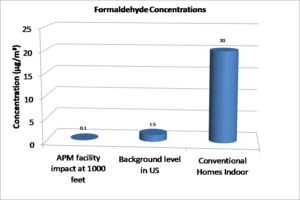

Emissions comparisons do not translate directly to air pollutant exposure. To provide further perspective on APM plants, Sanborn Head used dispersion modeling to estimate the ambient air quality impacts of a typical APM plant in comparison to concentrations commonly found in outdoor and indoor environments. An example for the HAP formaldehyde is illustrated below. Emissions from a typical APM plant are projected to increase the formaldehyde concentration in ambient air by 0.1 µg/m3. A typical background level of formaldehyde in ambient air is about 15 times higher (1.5 µg/m3), resulting mostly from the mobile source emissions and breakdown of other organic compounds in the atmosphere. Formaldehyde concentrations indoors can be much greater due to sources such as off-gassing from building materials. Concentrations in homes vary widely, but it is not unusual to detect 20 µg/m3 of formaldehyde indoors (200 times the projected impact from a typical APM plant). This pattern is similar for other pollutants emitted from APM facilities, for which dispersion modeling predicts incremental facility impacts to be below typical background levels.

The full report is available for download.

Posted In: Articles

Tagged In: Industrial, Research