Sanborn Head is currently piloting Bioelectrochemical (BEC) degradation to aerobically degrade petroleum hydrocarbons at a former refinery located in the eastern portion of the United States.

Key Components:

- Natural source zone depletion

- No remedial regent and no reaction byproducts

- Zero waste generation - eliminates waste hauling

- Net Energy Gain - Oxidation/Low Energy Input - Reduction

- GHG emissions reduction

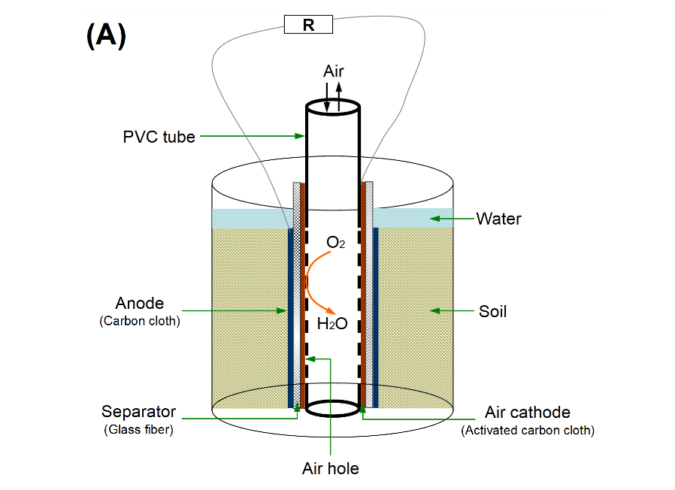

In the presence of aerobic conditions, microorganisms can degrade petroleum hydrocarbons using oxygen as the electron acceptor and the petroleum hydrocarbons as carbon and energy sources. Most remedial technologies which enhance aerobic degradation focus on providing oxygen to the subsurface to facilitate the process. Delivery of oxygen to the subsurface can be limited by the ability to deliver the oxygen effectively, especially in low permeability soils. Instead of using the traditional approach of providing oxygen to the subsurface, the BEC technology “pulls” the electrons towards the oxygen electron receptor in ambient air rather than pushing the oxygen through the subsurface. This process is accomplished through an anode being placed in the monitoring well in contact with the impacted groundwater and a cathode being placed at the ambient air interface in the well. The electrons are then transferred through the aquifer matrix from the anode to the cathode stimulating the biological degradation of the petroleum hydrocarbons by providing limitless access to oxygen. During the pilot test, Sanborn Head monitored concentrations of petroleum hydrocarbons in the groundwater, microbial populations, geochemical indicators of biological degradation and electrical current generated by the BEC electron transfer in order to document the success of the pilot test.

Sanborn Head proposed this technology because not only has it has been shown to be very effective at aerobically degrading petroleum hydrocarbons, it is a sustainable remediation technology. The BEC does not require an external energy source since the process is driven by the electron transfer. During the pilot test, a solar panel was added to the BEC unit which provided extra energy to the process, but the BEC process can function without the solar panel or any other external energy source. In addition, the degradation process results in the complete breakdown of the petroleum hydrocarbons to carbon dioxide and water, so no waste is generated using the BEC technology. Finally, the BEC process is re-useable, once an area is remediated the unit can be transferred to a different location and used to enhance aerobic degradation in that area representing a cost saving for the client and re-use of existing materials. The BEC technology allows a Site to reach remedial objectives, while also requiring no external energy, has zero waste products, and can be re-used numerous times at various locations.